China manufacturer panko bread crumb extruder machine 200-150kg/h:

Bread crumbs is a widely used food additive for deep fried food, and mainly for frying food surface, such as: fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious.The processing line replaces the traditional production technology.

LUERYA Bread Crumbs production line is effective with less waste materials.Through mixing,cooking,crushing and sifting ,this processing line can make various shapes and sizes bread crumb ,such as Japanese long needle shape,US granular shape, Snowflake shape and so on.

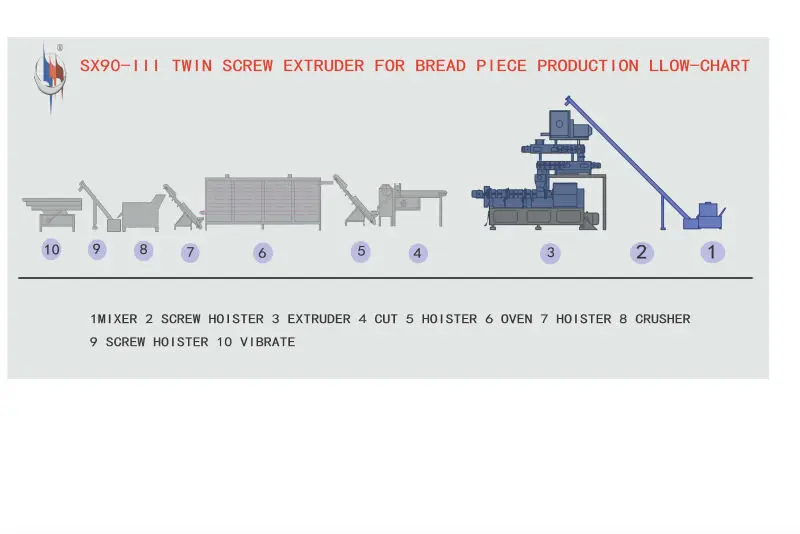

Flow chart of bread crumbs production line and it`s samples:

MIXING SYSTEM -- EXTRUDING SYSTEM -- PULLING AND CUTTING SYSTEM -- DRYING SYSTEM -- CRUSHING SYSTEM --- SELECTING SYSTEM

Technical parameter

| Model | Installed power | Power consumption | Throughput | Dimension |

| SX65 processing line | 65kw | 45kw | 120-150kg/h | 25x1.0x1.8m |

| SX70 processing line | 84kw | 63kw | 200-300kg/h | 29x3x3m |

| SX85 processing line | 120kw | 80kw | 300-500kg/h | 30x3.2x3.5m |

| SX90 processing line | 167kw | 125kw | 800-1000kg/h | 35x3.2x3.5m |

Feature

This processing line takes a new process for bread crumbs production. It is from powder for wheat flour to bread crumbs automatically. No bread produced during the whole process. So no bread crust appeared. The final product is bright white and with good texture.

The output of our bread crumbs processing line is very reasonable: it can be (120-1000kg/hr).

And the operation is very simple, the production time is within 20 minutes from raw material to final product.

Allocation of Breadcrumb Processing Line as reference(not fixed): Mixer-Screw conveyor-Twin screw extruder-Cutter-Hoister-Humid crusher-Air conveyor-Multi-layer roasting oven-Air conveyor(or vacuum feeding machine)-Grading sifter.

bread crumbs samplesc produced by this processing line

<template class="visibility">

China manufacturer panko bread crumb extruder machine 200-150kg/h:

Bread crumbs is a widely used food additive for deep fried food, and mainly for frying food surface, such as: fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious.The processing line replaces the traditional production technology.

LUERYA Bread Crumbs production line is effective with less waste materials.Through mixing,cooking,crushing and sifting ,this processing line can make various shapes and sizes bread crumb ,such as Japanese long needle shape,US granular shape, Snowflake shape and so on.

Flow chart of bread crumbs production line and it`s samples:

MIXING SYSTEM -- EXTRUDING SYSTEM -- PULLING AND CUTTING SYSTEM -- DRYING SYSTEM -- CRUSHING SYSTEM --- SELECTING SYSTEM

Technical parameter

| Model | Installed power | Power consumption | Throughput | Dimension |

| SX65 processing line | 65kw | 45kw | 120-150kg/h | 25x1.0x1.8m |

| SX70 processing line | 84kw | 63kw | 200-300kg/h | 29x3x3m |

| SX85 processing line | 120kw | 80kw | 300-500kg/h | 30x3.2x3.5m |

| SX90 processing line | 167kw | 125kw | 800-1000kg/h | 35x3.2x3.5m |

Feature

This processing line takes a new process for bread crumbs production. It is from powder for wheat flour to bread crumbs automatically. No bread produced during the whole process. So no bread crust appeared. The final product is bright white and with good texture.

The output of our bread crumbs processing line is very reasonable: it can be (120-1000kg/hr).

And the operation is very simple, the production time is within 20 minutes from raw material to final product.

Allocation of Breadcrumb Processing Line as reference(not fixed): Mixer-Screw conveyor-Twin screw extruder-Cutter-Hoister-Humid crusher-Air conveyor-Multi-layer roasting oven-Air conveyor(or vacuum feeding machine)-Grading sifter.

bread crumbs samplesc produced by this processing line

</template>

English

English 简体中文

简体中文